Custom Steel Structure Weldment Metal Parts Bending Welding Fabrication Frame Construction Services

Custom Steel Structure Weldment Metal Parts Bending Welding Fabrication Frame Construction Services Company Profile: Shu

Description

Basic Info.

| Processing Service | Bending, Welding, Decoiling, Cutting, Punching |

| Delivery Time | 30 Days |

| Package | Standard Sea Worthy Package |

| MOQ | 1 Ton |

| Width | as Your Requirement |

| Length | Customized |

| Technique | Hot-Rolled Steel Plate Shipbuilding |

| Special Use | Construction |

| Transport Package | Standard Sea Worthy Export Packing |

| Specification | SPCC |

| Trademark | SHUOPU |

| Origin | Guangdong, China |

| HS Code | 73269090 |

Product Description

Custom Steel Structure Weldment Metal Parts Bending Welding Fabrication Frame Construction Services

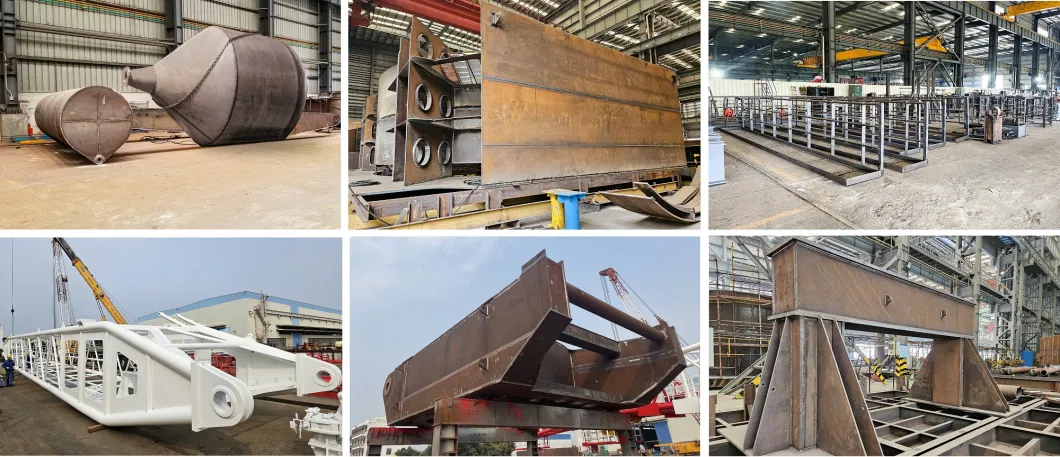

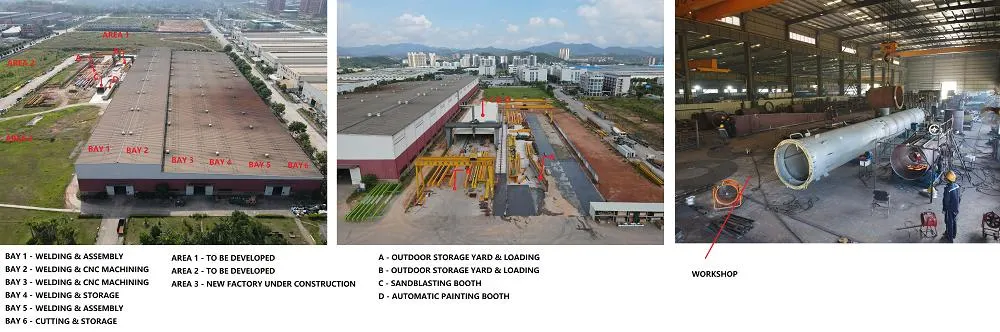

Shuopu is a world-class leading manufacturer of high-quality standard OEM metal fabrication for various applications such as Shipbuilding, Marine Construction, Offshore Drilling, Offshore Industries, Mining Equipment, etc. ShuoPu Machinery Technology Co., Ltd was founded in 2007 with more than 16 years of experience in OEM custom sheet metal fabrication, CNC Machining, Welding, Precision parts & Assembling, Blasting & painting. Shuopu is equipped with a plasma cutting machine, CNC cutting machine, flame cutting machine and sawing machine, etc for different cutting needs.

Shuopu possesses a complete supply chain that can satisfy various fields of application. You can source diverse kinds of structural steel, specific mechanical parts and specific international grade raw materials for specified applications such as Marine Engineering, Offshore Industries, Mining Projects, Underground Drilling and even aviation materials.

Product Description:

| General Capacity | Metal Fabrication, Steel Metal Weldment, Steel Fabrication, Steel Structure Weldment, Metal Parts Bending Welding Frame Construction Services |

| Fabrication Method | Bending, CNC Machining, Cutting, Forming, Machining, Punching, Rolling, Sawing, Shearing, Welding |

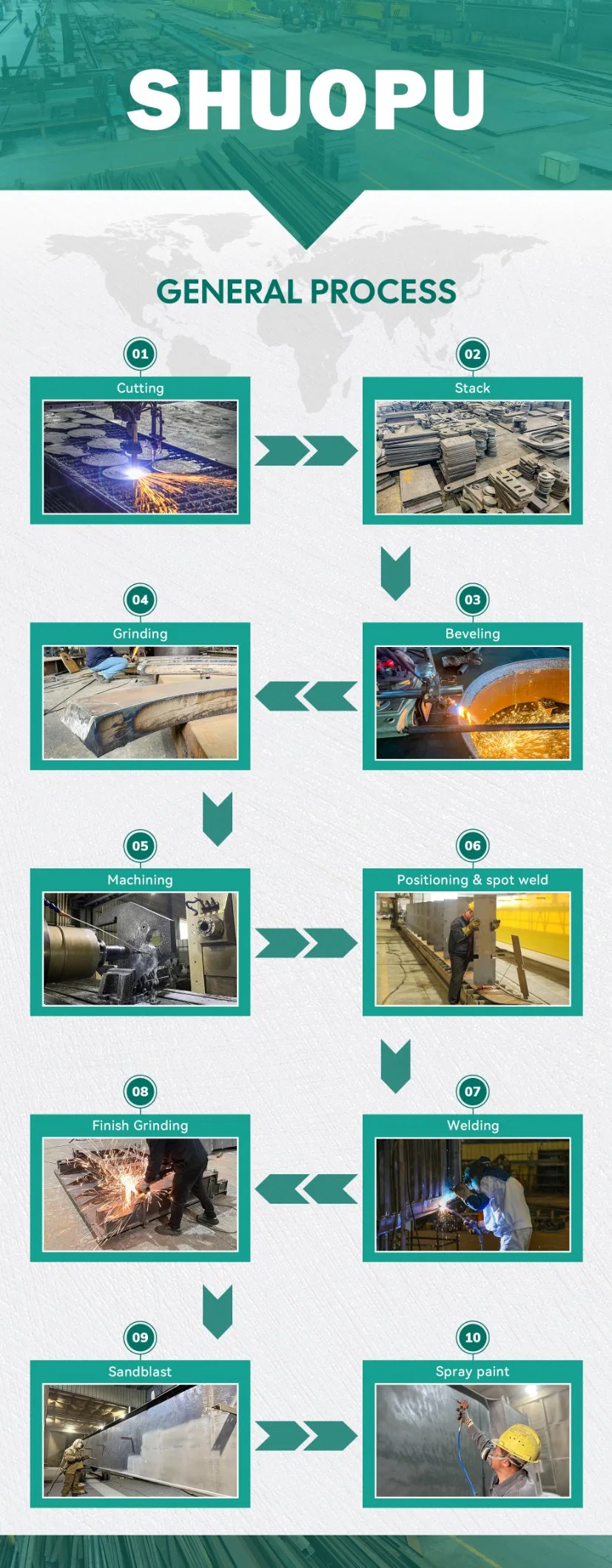

| Production Process | Laser cutting, Punching, Deburring, Bending, Pressing, Welding, Riveting, Grinding |

| Standard | AiSi, ASTM, BS, DIN, JIS, GS, ABS, CCS, BV, etc. |

| Surface Treatment | Powder Coating, Painting, Galvanizing, Electroplating, Anodising,Chromeplating |

| Industry Focus | Shipbuilding, Marine Construction, Offshore Drilling, Offshore Industries, Mining Equipment, Mined Products, Underground Infrastructure |

| Service Type | OEM Metal Fabrication |

| Certificate | ISO9001, UT & RT qualifications, CE |

Other Cases:

Strict Processing and Quality Control

Shuopu insists on strict quality control which is the core spirit of company development. The steel order is for the specific international grade, application and service temperature, so all raw materials will be inspected by Shuopu quality inspectors before entering the warehouse. The split diagrams are finished by the design department, then will eventually be sent to the production department and classified and dispatched to various positions. Learning and checking the split diagram data is necessary to work for them before starting production, which can improve production efficiency.

Quality Control

Horizontal measurement, vertical measurement, dimension measurement, etc. will occur in every production step, to ensure the specifications reach standard. NDT, including VT, MT, PT, UT and RT, are the common inspection methods for the finished items.

Trial Assembly

We provide assembly test services based on client's requests. Trial Assembly can ensure the accuracy of welding parts and reduce the error cost of customers.

Producing Base

ShuoPu producing base covers an area of 45,000 sqm, which allow our large order capacity, fast delivery, assembly capacity, etc... We provided diverse industry projects of customized metal products to over 60 countries, such as Germany, Austria, America, Canada, Switzerland, Denmark, The United Arab Emirates and Ecuador, etc. And Shuopu meets the highest industry standard according to the user's area. Our abundant experienced and certified engineering team absolutely could create the precise drawing according to your details and requirements. If you have all the required information and design drawings for a quote, get started, our experts are ready to assist you within 5 hours concerning your request.

Packaging & Shipping

We have different ways of packing, we make the production plan and plan its packing way according to its destination, mode of transportation, specifications, etc. After the production is over, we still need to combine the packaging specifications and transportation methods to formulate plans including how to place, how to load the cabinets, the equipment required for the cabinets, and the time for loading the cabinets, etc...

Our TeamFAQ:Q1: Are you a trading company or manufacturer?

A: We are a manufacturer engaging in the field of metal products for more than 20 years.

Q2:How much is the freight?

We will decide according to your mode of shipping and quantity, it needs you to provide us with a specific mode of transportation(by sea or air), which port or airport to arrive at.

Q3: Do you accept retail orders? What is the MOQ required?

A: Yes, we accept retail orders. MOQ is negotiable, free to contact us for discussion.

Q4: Do you provide ODM/OEM service?

A: Yes. OEM & ODM are available, you can show us the design plan, and it is better to ship us your original sample.

From the concept to finished goods, we do all (design, prototype reviewing, tooling and production) in the factory.

Q5:What are the finished quality testing methods?

A: MT, PT, UT, RT, and VT are our main methods for quality inspection.Q6:If there is no request from the customer, what is the spot check rate of the factory on the weld quality?

A: Normally 20% unless NDT is required.

Get a Quote for Fee

Contact us right now for a quote and learn more about how we can save your cost. You can always expect our prompt attention. And we look forward to establishing a long-run business relationship with you. We not only want to be your metal parts supplier but also your partner in China. Welcome send drawings and samples to us for offer.

Prev: Robot Welding and 3 and 4 Axis Machining CNC Machining Service

Next: Heavy Structual OEM Steel Welding Fabrication Work Service

Our Contact

Send now